BP Series-Standard AGM Battery

-

Using oxygen recombination technology: maintenance-free

-

Pb-Ca-Sn alloy for plate grids: less gassing and less self-discharging

-

High quality AGM separator: extend cycle life and prevents micro short circuit

-

ABS material: increases the strength of battery container (Flame-retardant ABS is optional)

-

High purity raw material: ensures low self discharge rate

-

Silver-coated copper terminals, brass insert terminals and lead terminals improve the electric conductivity

Authentic Numbers for You to Choose Us

Roughly over 12,000pcs 12V 7Ah per day

Over 100 workers + automatic production lines

Technicians with 20+ years of experience

Running stock for regular models (7Ah, 100Ah, 200Ah, etc.)

Every penny on material and quality control other than too much advertising and redundant management

Popular Reference from Our Customers' Feedback

| Model |

Voltage

|

Capacity (Ah)

|

Terminal | |||

|---|---|---|---|---|---|---|

| BP4-4 | 4V | 4.0 | 0.44 / 0.97 | 47×47×101 mm | 106 mm / 4.18 in | T1 |

| BP4.5-4 | 4V | 4.5 | 0.47 / 1.04 | — | — | — |

| BP1.2-6 | 6V | 1.2 | 0.28 / 0.62 | 97×24×53 mm | 58 mm / 2.29 in | T1 |

| BP2.8-6 | 6V | 2.8 | 0.55 / 1.21 | 66×33×99 mm | 104 mm / 4.1 in | T1 |

| BP3.2-6 | 6V | 3.2 | 0.64 / 1.41 | 134×35×61 mm | 66 mm / 2.6 in | T1 |

| BP4-6 | 6V | 4.0 | 0.68 / 1.5 | 70×47×100 mm | 105 mm / 4.14 in | T1 |

| BP4.5-6 | 6V | 4.5 | 0.72 / 1.59 | — | — | — |

| BP5-6 | 6V | 5.0 | 0.8 / 1.76 | — | — | — |

| BP7-6 | 6V | 7.0 | 1.08 / 2.38 | 151×35×95 mm | 100 mm / 3.94 in | T1/T2 |

| BP10-6 | 6V | 10.0 | 1.6 / 3.53 | 151×50×95 mm | 100 mm / 3.94 in | T1/T2 |

| BP12-6 | 6V | 12.0 | 1.72 / 3.79 | — | — | — |

| BP0.8-12 | 12V | 0.8 | 0.32 / 0.71 | 96×25×62 mm | 62 mm / 2.44 in | Plug |

| BP1.2-12 | 12V | 1.2 | 0.51 / 1.12 | 97×43×52 mm | 57 mm / 2.25 in | T1 |

| BP2.3-12 | 12V | 2.3 | 0.9 / 1.98 | 178×35×61 mm | 66 mm / 2.6 in | T1 |

| BP2.6-12 | 12V | 2.6 | 0.8 / 1.76 | 70×47×98 mm | 103 mm / 4.06 in | T1 |

| BP3.2-12 | 12V | 3.2 | 1.2 / 2.65 | 134×67×61 mm | 66 mm / 2.6 in | T1 |

| BP3.5-12 | 12V | 3.5 | 1.33 / 2.93 | — | — | — |

| BP4-12 | 12V | 4.0 | 1.37 / 3.02 | 90×70×101 mm | 106 mm / 4.18 in | T1/T2 |

| BP4.5-12 | 12V | 4.5 | 1.42 / 3.13 | — | — | — |

| BP5-12 | 12V | 5.0 | 1.54 / 3.4 | — | — | — |

| BP6.5-12 | 12V | 6.5 | 2.0 / 4.41 | 151×65×95 mm | 100 mm / 3.94 in | T1/T2 |

| BP7-12 | 12V | 7.0 | 2.04 / 4.49 | — | — | — |

| BP7.5-12 | 12V | 7.5 | 2.16 / 4.76 | — | — | — |

| BP8-12 | 12V | 8.0 | 2.23 / 4.92 | — | — | — |

| BP9-12 | 12V | 9.0 | 2.46 / 5.42 | — | — | — |

| BP10-12H | 12V | 10.0 | 2.65 / 5.84 | 151×65×111 mm | 116 mm / 4.57 in | T1/T2 |

| BP10-12 | 12V | 10.0 | 3.15 / 6.95 | 151×98×95 mm | 100 mm / 3.94 in | T1/T2 |

| BP12-12 | 12V | 12.0 | 3.35 / 7.39 | — | — | — |

| BP14-12 | 12V | 14.0 | 3.76 / 8.29 | — | — | — |

| BP17-12 | 12V | 17.0 | 4.95 / 10.9 | 181×77×167 mm | 167 mm / 6.58 in | T3/T8 |

| BP18-12 | 12V | 18.0 | 5.18 / 11.4 | — | — | — |

| BP20-12 | 12V | 20.0 | 5.48 / 12.1 | — | — | — |

| BP24-12 | 12V | 24.0 | 8.0 / 17.6 | 174×166×125 mm | 125 mm / 4.93 in | T3/T8 |

| BP28-12 | 12V | 28.0 | 8.2 / 18.1 | 166×125×175 mm | 175 mm / 6.9 in | T6/T8 |

| BP33-12 | 12V | 33.0 | 10.5 / 23.2 | 195×130×153 mm | 164 mm / 6.46 in | T7/T9 |

| BP40-12 | 12V | 40.0 | 12.5 / 27.6 | 196×166×170 mm | 170 mm / 6.7 in | T7/T9 |

| BP55-12 | 12V | 55.0 | 17.5 / 38.6 | 229×138×208 mm | 211 mm / 8.31 in | T5/T15 |

| BP65-12 | 12V | 65.0 | 20.5 / 45.2 | 350×169×179 mm | 179 mm / 7.05 in | T5/T15 |

| BP70-12 | 12V | 70.0 | 21.7 / 47.8 | 260×168×211 mm | 214 mm / 8.43 in | T5/T15 |

| BP80-12 | 12V | 80.0 | 23.0 / 50.7 | 260×168×211 mm | 214 mm / 8.43 in | T5/T15 |

| BP90-12 | 12V | 90.0 | 26.3 / 58.0 | 307×168×211 mm | 214 mm / 8.4316 in | T5/T15 |

| BP100-12 | 12V | 100.0 | 29.6 / 65.3 | 330×173×217 mm | 220 mm / 8.67 in | T5/T14 |

| BP120-12 | 12V | 120.0 | 35.6 / 78.5 | 406×173×208 mm | 238 mm / 9.38 in | T5/T14 |

| BP150-12 | 12V | 150.0 | 43.6 / 96.1 | 484×170×240 mm | 240 mm / 9.46 in | T5/T14 |

| BP180-12 | 12V | 180.0 | 56.5 / 124.0 | 522×238×218 mm | 221 mm / 8.71 in | T5/T10 |

| BP200-12 | 12V | 200.0 | 59.5 / 131.0 | 522×238×218 mm | 221 mm / 8.71 in | T5/T10 |

| BP230-12 | 12V | 230.0 | 66.0 / 145.0 | 521×269×203 mm | 206 mm / 8.12 in | T5/T10 |

| BP250-12 | 12V | 250.0 | 71.5 / 157.0 | 520×267×220 mm | 223 mm / 8.79 in | T5/T10 |

All specifications are subject to change without notice.

Total height includes terminals. Dimensions format: Length × Width × Height.

What's the Steps of Making a AGM Battery

Plate Packing

Plate Welding

Single Cell Grouping

Battery Casing

Polarity Marking

Battery Curing

Acid Filling

Battery Charging

Battery Printing

Battery Packaging

Comprehensive Quality Control Process

Our commitment to excellence is reflected in our rigorous steps quality control system, ensuring every product meets the highest industry standards.

1.Plate thickness variations can lead to uneven current distribution. The selection should be based on the specific application requirements and usage patterns of the battery. Thicker plates: better for deep cycle, better resistance to grid corrosion and active material shedding. Thinner plates: Better for high-rate discharge, faster charging

2.Short Circuit Testing is an important quality control measure in the manufactuering process. It is a 100% test for every single battery. There are many reasons that lead to battery short cirbuit: separator defects, plate misalignment, poor welding connections, material impurities, grid defects. It prevents catastrophic battery failures, reduces risk of thermal runaway in advance

3.Air-tightness testing is critical for ensuring battery quality and performance. It involves pressurizing the battery and monitoring pressure retention over time. A properly sealed battery prevents electrolyte leakage, maintains internal pressure, and ensures optimal chemical reactions

4.Weight inspection is another measure that helps us detect that whether the performance meet customers' requirement, Even the specification of the same model varies according to different market, application and the price acceptance of end user. Any significant weight deviation may indicate manufacturing issues requiring immediate attention, making this simple yet effective test essential for quality assurance

5.This multi-functional test reveals: actual capacity verification, charging efficiency, internal resistance characteristics, cycle life performance.The results help identify manufacturing defects, predict battery lifespan, and ensure product quality. Through controlled charging and discharging cycles, we can validate if batteries meet specifications and customer requirements. This testing is crucial for maintaining high product standards and reliability in real-world applications.

6.Refering to the battery distributors and wholesalers, they usually do not have the professional testing euipment like battery manufacturers. The battery system tester offers valuable benefits: Quick and accurate voltage readings, Instant internal resistance measurement, Real-time state of charge indication, Minimal training required for operation. We will also use this tool to unify testing criteria with customers.

Customizable Colors for Enhanced Brand Value

Elevate your product portfolio with our versatile color customization options. Our advanced color solutions not only enhance visual appeal but also provide strategic advantages in brand differentiation, market positioning, and operational efficiency. Discover how our color customization can transform your business strategy.

Brand Identity & Recognition

- • Helps establish unique brand presence

- • Makes products instantly recognizable

- • Strengthens corporate identity

- • Creates visual differentiation

Market Segmentation

- • Different colors for product lines

- • Easy identification of battery types

- • Helps in inventory management

- • Reduces handling errors

Customer Experience

- • Matches equipment aesthetics

- • Provides premium feel

- • Coordinates with color schemes

- • Enhances visual appeal

Marketing Advantages

- • Creates unique selling proposition

- • Attracts attention in displays

- • Enables premium pricing

- • Supports promotions

Lead Time, Package & Shipping

Lead Time

-

25-30 days for a 20ft container

-

10-15 days for 1-2 pallets trial order

-

Drop shipment for general stocking items

Shipping

We are free to recommend you the experts who specialize in battery shipping and logistics.

Package

Professional packaging ensures your batteries arrive safely at their destination.

Single battery

1pc/PE bag

pcs/carton

cartons/pallet

pallets/container

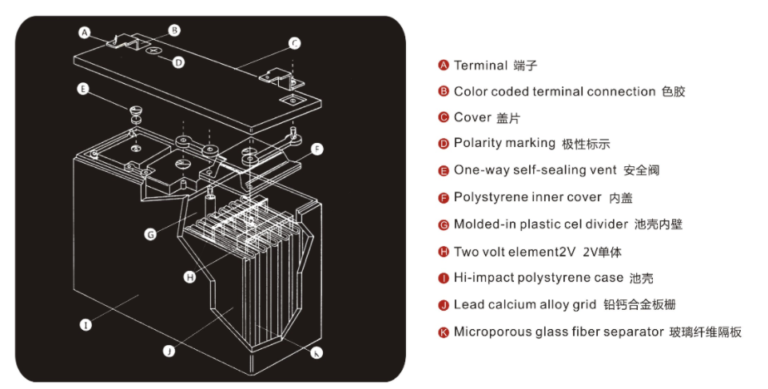

The Inner Structure of AGM Battery

Lead

China #1 pure lead, no recycle

Grid

Newly-designed PbCa alloy grids, anti-corrosion, good conductivity, improve the utilization rate of lead paste and reaction efficiency

Housing

ABS with fire resistance and waterproof, UL94-HB UL94-0 optional. No any recycled plastic.

Seperators

high quality AGM, offers superior electrolyte absorption and retaining ability, excellent ion conductivity

Terminal

lead or copper with maximum conductivity

Safety vavle

automatically release the excess gasses and reduce electrolyte evaporation

Battery Maintenance Simple Guide

Proper maintenance ensures optimal performance and longevity of your BEVAULT batteries. Follow these tips for best results.

Charging Method

| APPLICATION | STANDBY USE | CYCLE USE |

|---|---|---|

| Charging Method | Constant voltage | |

| Setting Voltage (V/cell) | 2.25~2.30 | 2.40~2.50 |

| Temperature Factor | -3.0mV/°C/cell | -5.0mV/°C/cell |

| Max. Charge Current (Ca) | 0.3 | |

| Charge Time |

Discharge 100%

24h Discharge 50%20h |

Discharge 100%

16h Discharge 50%10h |

| Temperature (°C) | -15°C~40°C | |

Handing Instruction

- Do not short the terminals.

- Do not place the battery near or in fires.

- Do not use the battery in a container or bag without proper ventilation.

- Operate at a temperature between -15°C to 50°C. But for cycle use, the 5°C to 35°C temperature range is recommended.

- To properly store the battery, remove battery from equipment or charge and store in a dry and cool place.

- Immediately recharge after discharging.

- If sulfuric acid from the battery is spilled on skin or clothing, wash immediately with water. If acid comes in contact with eyes, flush with large amounts of water and immediately see a doctor.

- To obtain maximum life, the ripple current at the RMS forward current of the charger should be regulated to 10% less than its output value.

- Avoid mixed use of batteries. Different capacities, histories, or manufacturers of batteries may cause damage to the batteries or other equipment’s.

Contact Us

Get Your Battery With Easy

At BEVAULT, We turn complex Into Simple! Follow the following 3 steps to start today!

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

Approve for Mass Production

We will start mass production after getting your approval and deposit, and we will handle the shipment.