Is an AGM Battery a Deep Cycle Battery?

Confusion about AGM and deep cycle batteries leads to costly purchasing mistakes. Many buyers assume all AGM batteries are deep cycle, resulting in premature battery failure and wasted investment.

Not all AGM batteries are deep cycle batteries. While AGM describes the battery's construction (Absorbed Glass Mat), deep cycle refers to its performance characteristics. Some AGM batteries are designed for deep cycling, while others are made for starting applications.

After manufacturing both types at BEVAULT for over a decade, We've seen countless cases of mismatched applications. Let me clear up the confusion and help you make the right choice for your needs.

Is an AGM Battery the Same as a Deep Cycle?

Buyers often conflate AGM construction with deep cycle capability, leading to expensive mistakes. I frequently encounter customers who've purchased standard AGM batteries for deep cycle applications, only to face early failures.

AGM and deep cycle are different characteristics. AGM refers to the electrolyte being absorbed in glass mat separators, while deep cycle indicates the battery's ability to handle repeated deep discharges. Some AGM batteries are specifically engineered for deep cycling with enhanced plate design.

Let's explain the key differences based on our manufacturing experience at BEVAULT:

Understanding AGM vs Deep Cycle Characteristics

Manufacturing both types of batteries has given us unique insights into their differences:

| Feature | Standard AGM | Deep Cycle AGM |

|---|---|---|

| Plate Thickness | Thinner plates | Thicker plates |

| Tin Content | 0.5-0.7% | 0.8-1.2% |

| Grid Design | Higher surface area | More robust structure |

| Cycle Life | 200-300 cycles | 400+ cycles |

| Discharge Depth | 30% recommended | 50-80% possible |

We remember a solar installer who bought standard AGM batteries for a residential solar system. Within six months, the batteries lost significant capacity. When they switched to our deep cycle AGM batteries with optimized plate composition, their system has been running efficiently for over three years.

What Is the Main Disadvantage of an AGM Battery?

Many users discover AGM battery limitations only after purchase. Understanding these drawbacks beforehand can prevent costly mistakes and system failures.

The main disadvantage of AGM batteries is their sensitivity to overcharging, which can cause permanent damage. They also cost more than flooded batteries, have less tolerance for high-temperature environments, and cannot be refilled or serviced internally.

Through our experience manufacturing AGM batteries, we've identified several key challenges:

AGM Battery Limitations and Solutions

Based on customer feedback and our factory testing, here are the main disadvantages and ways to address them:

-

Charging Sensitivity

- Problem: Overcharging causes irreversible damage

- Solution: Use voltage-controlled chargers with AGM-specific settings

-

Cost Considerations

- Problem: 15-30% more expensive than flooded batteries

- Solution: Factor in lower maintenance costs and longer life when properly maintained

-

Temperature Sensitivity

- Problem: Performance degrades faster in high temperatures

- Solution: Implement proper ventilation and temperature control

-

Internal Access

- Problem: Cannot add water or check specific gravity

- Solution: Use voltage monitoring and load testing for maintenance

We once helped a UPS system operator in Southeast Asia who was experiencing frequent AGM battery failures1. We discovered their charging voltage2 was set too high for the warm climate. After adjusting the voltage and improving ventilation, their battery life doubled.

How Do I Know if My Deep Cycle Battery is AGM?

Identifying battery types can be confusing, leading to improper maintenance and charging. Many users damage their batteries by applying incorrect maintenance procedures.

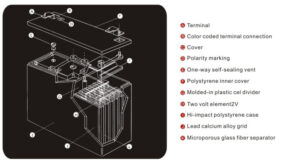

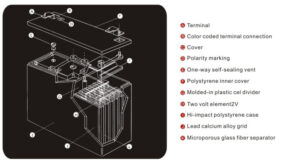

You can identify an AGM deep cycle battery by checking for sealed construction (no filling caps), flat or button-style terminals, and manufacturer markings indicating "AGM" or "Absorbed Glass Mat." These batteries are completely sealed and maintenance-free.

At BEVAULT, we mark our AGM batteries clearly, but not all manufacturers do. Here's how to identify them:

Physical Characteristics of AGM Batteries

Our quality control department uses these indicators to verify battery types:

-

External Features

- No removable caps (unlike flooded batteries)

- Typically has flat top design

- Often includes "AGM" or "Sealed" marking

- Pressure relief valves visible

-

Terminal Types

- Usually threaded terminals or SAE posts

- Clean, corrosion-resistant design

-

Case Construction

- Completely sealed design

- Often more robust than flooded cases

- May have pressure relief valves

We recently assisted a Portuguese distributor who had mixed AGM and flooded batteries in their inventory. We implemented a simple identification system using these characteristics, preventing costly installation mistakes.

What Type of Battery is an AGM?

Understanding AGM technology helps prevent misuse and ensures proper application selection. Many users misunderstand AGM's place in the battery hierarchy, leading to application mismatch.

An AGM battery is a valve-regulated lead-acid (VRLA) battery where the electrolyte is absorbed in glass mat separators. It's a sealed, maintenance-free design that prevents acid spills and allows installation in any orientation except upside-down.

From our years of manufacturing experience at BEVAULT, We can explain the unique aspects of AGM technology:

AGM Battery Technology Overview

The evolution of AGM technology represents a significant advancement in battery design:

| Feature | Description | Benefit |

|---|---|---|

| Glass Mat Construction | Fiberglass mat holds electrolyte | Prevents acid spills, allows flexible mounting |

| Recombinant Design | Oxygen cycle prevents water loss | Maintenance-free operation |

| Pressure Regulation | VRLA system controls gas release | Safe operation in enclosed spaces |

| Grid Technology | Enhanced plate formulation | Better performance in specific applications |

Beyond these basic features, modern AGM manufacturing has evolved significantly. When I started at BEVAULT, we used higher tin content in our plates. Today, we achieve better performance with optimized grid designs and improved manufacturing processes.

Our AGM manufacturing process involves several critical steps:

-

Plate Manufacturing

- Precise lead alloy mixing

- Controlled curing process

- Optimized grid design

-

AGM Separator Preparation

- Specific glass fiber composition

- Controlled thickness and density

- Precise electrolyte absorption

-

Assembly Process

- Automated stacking

- Compression control

- Heat sealing

-

Quality Control

- Vacuum testing

- Capacity verification

- Charge acceptance testing

We recently guided a UK solar installer through selecting the right AGM batteries for their application. They were particularly interested in our manufacturing process and how it affects battery performance. After understanding the technology, they chose our deep cycle AGM batteries with optimized plate composition, resulting in a 40% improvement in system performance compared to their previous setup.

While AGM describes a battery's construction method, not all AGM batteries are deep cycle. Understanding these differences, along with proper identification and application matching, is crucial for optimal battery performance and longevity. Choose batteries based on your specific needs rather than construction type alone.