How Long Do AGM Batteries Last?

Unexpected AGM battery failures can disrupt your operations and lead to costly downtime. Many users experience shortened battery life due to misunderstanding proper maintenance and usage patterns.

AGM batteries typically last 3-5 years under normal conditions. However, actual lifespan varies significantly based on usage patterns, environmental conditions, charging practices, and maintenance quality. Some can last up to 8 years with optimal care.

At BEVAULT, we've manufactured millions of AGM batteries and tracked their performance across different applications. Let me share what really determines how long your AGM battery will last.

What Is the Life Expectancy of an AGM Battery?

Users often receive conflicting information about AGM battery life expectancy. This confusion leads to unrealistic expectations and improper maintenance schedules.

AGM batteries are designed to last 3-5 years in standard applications. However, actual lifespan depends heavily on operating conditions. In ideal situations with proper maintenance, temperature control, and correct charging, they can exceed their design life.

![]()

From our extensive manufacturing experience at BEVAULT, we've identified key factors that influence battery life:

AGM Battery Lifespan Factors

Based on our factory data and customer feedback, here's what really affects AGM battery life:

| Factor | Impact | Optimal Conditions |

|---|---|---|

| Temperature | High | 20-25°C (68-77°F) |

| Depth of Discharge | High | Keep above 50% charge |

| Charging Method | Critical | Use proper AGM charger |

| Maintenance | Moderate | Regular inspections |

| Usage Pattern | High | Consistent use better than storage |

I remember a telecommunications customer in Spain who achieved 7+ years from their AGM batteries by maintaining strict temperature control and proper charging protocols1. This significantly exceeded the typical 3-5 year lifespan we usually see.

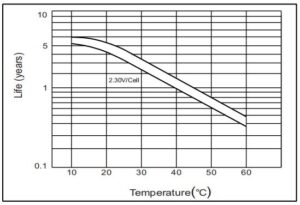

Our testing shows that controlling these factors can double or even triple battery life:

-

Temperature Management

- Every 10°C increase halves battery life

- Climate control investment pays off

- Proper ventilation essential

-

Charging Practices

- Use temperature-compensated charging

- Maintain proper float voltage

- Avoid overcharging

-

Usage Patterns

- Regular cycling better than long storage

- Avoid deep discharges

- Keep batteries above 50% charge

What Is the Main Disadvantage of an AGM Battery?

Cost concerns often drive purchase decisions, but focusing solely on initial price can lead to higher long-term expenses. Understanding limitations helps make informed decisions.

The main disadvantage of AGM batteries is their higher initial cost compared to flooded batteries. They're also sensitive to overcharging, can't be refilled, and are less forgiving of charging errors. However, their maintenance-free nature often offsets these drawbacks.

Through our manufacturing experience, we've identified several challenges users face:

Key AGM Battery Limitations

Our quality control team regularly analyzes customer feedback to understand common issues:

-

Cost Considerations

- 15-30% higher initial investment

- Special charging equipment needed

- Cannot be refurbished

-

Technical Limitations

- Sensitive to charging parameters

- No electrolyte maintenance possible

- Temperature sensitive

-

Performance Trade-offs

- Less tolerant of overcharging

- More affected by high temperatures

- Cannot recover from deep discharge

One of our UK distributors initially hesitated at AGM costs but found that reduced maintenance needs and longer life made them more economical over time.

How Do I Know if My AGM Battery Needs Replacing?

Many users miss early warning signs of battery failure, leading to unexpected system downtime. Learning to recognize these signs can prevent costly interruptions.

Replace your AGM battery when you notice: significant capacity loss (more than 20%), inability to hold charge, swollen case, excessive heat during charging, or age exceeding 5 years. Regular voltage testing can help identify issues before failure.

At BEVAULT, we recommend these testing procedures:

Signs of AGM Battery End-of-Life

Based on our technical support experience:

| Warning Sign | What It Means | Action Required |

|---|---|---|

| Voltage Drop | Internal damage | Test under load |

| Slow Charging | Lost capacity | Check charging system |

| Swelling | Internal failure | Replace immediately |

| Age >5 years | Natural aging | Plan replacement |

| Heat During Charge | Internal resistance | Safety concern |

A solar installer in Portugal shared how implementing our battery monitoring protocol helped them predict failures and schedule replacements without system downtime.

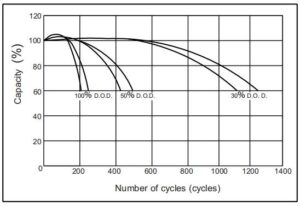

Do AGM Batteries Lose Capacity Over Time?

Natural capacity loss in AGM batteries confuses many users. Understanding this process helps set realistic expectations and plan for replacement.

Yes, AGM batteries gradually lose capacity over time, typically 2-3% per year under normal conditions. This process accelerates with high temperatures, improper charging, and deep discharges. Regular capacity testing helps track this decline.

Our laboratory testing reveals consistent patterns in capacity loss:

Understanding AGM Battery Capacity Loss

Through years of manufacturing and testing, we've documented typical capacity decline:

-

Normal Aging Process

- First year: 1-2% loss

- Subsequent years: 2-3% annual loss

- Accelerates after 3-4 years

-

Factors Affecting Capacity Loss

- Operating temperature

- Discharge depth

- Charging accuracy

- Usage frequency

-

Monitoring Methods

- Regular voltage testing

- Load testing

- Capacity measurement

- Performance tracking

I recently worked with a Netherlands UPS distributor who implemented our capacity monitoring system. They now replace batteries proactively at 80% capacity, preventing critical system failures.

Management practices that minimize capacity loss:

-

Temperature Control

- Keep batteries at 20-25°C

- Monitor ambient temperature

- Provide adequate ventilation

-

Usage Optimization

- Avoid deep discharges

- Use appropriate charging voltage

- Regular cycling better than storage

-

Maintenance Schedule

- Monthly voltage checks

- Quarterly load tests

- Annual capacity testing

AGM batteries typically last 3-5 years, but proper maintenance, temperature control, and charging practices can extend their life significantly. Understanding warning signs and implementing regular testing helps maximize investment return and prevent unexpected failures.

-

Learning about optimal charging protocols can help you maximize the lifespan and efficiency of your batteries. ↩